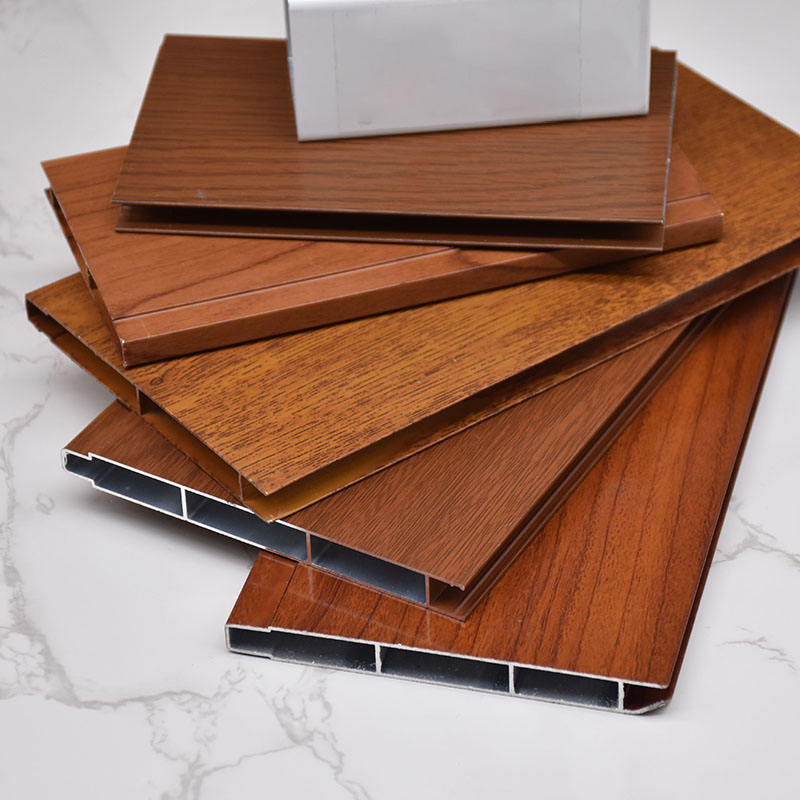

he application of 500-word wood grain aluminum profiles can be found in various fields. Here are a few examples:

1. Architecture: Wood grain aluminum profiles are used in the construction of buildings, particularly for doors, windows, and curtain walls. The wood grain finish gives the appearance of natural wood, providing a warm and aesthetic touch to the building’s exterior.

2. Interior Design: Wood grain aluminum profiles are commonly used for interior decoration and furniture. They can be used for wall paneling, ceilings, partitions, and cabinets, offering a stylish and durable alternative to traditional wooden materials.

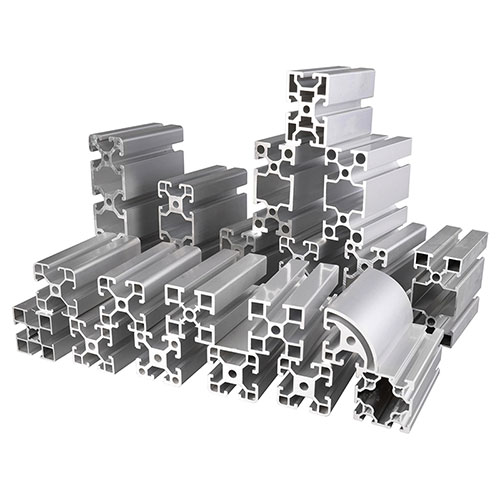

3. Industrial Applications: Wood grain aluminum profiles are used in the manufacturing sector for various purposes. They can be used to create frames for solar panels, automotive trim, and electronic enclosures, among other applications. The wood grain finish adds an attractive design element to these products.

4. Retail and Commercial Spaces: Wood grain aluminum profiles find applications in retail stores, restaurants, and other commercial spaces. They can be used for display fixtures, signage, and storefronts, creating a modern and inviting ambiance.

5. Transportation: Wood grain aluminum profiles are used in the transportation industry for both interior and exterior applications. They can be used for decorative trims in vehicles, such as buses, trains, and boats, offering a luxurious and sophisticated appearance.

Overall, the application of 500-word wood grain aluminum profiles is diverse and can be seen in various industries, contributing to both functional and aesthetic aspects of different products and structures.