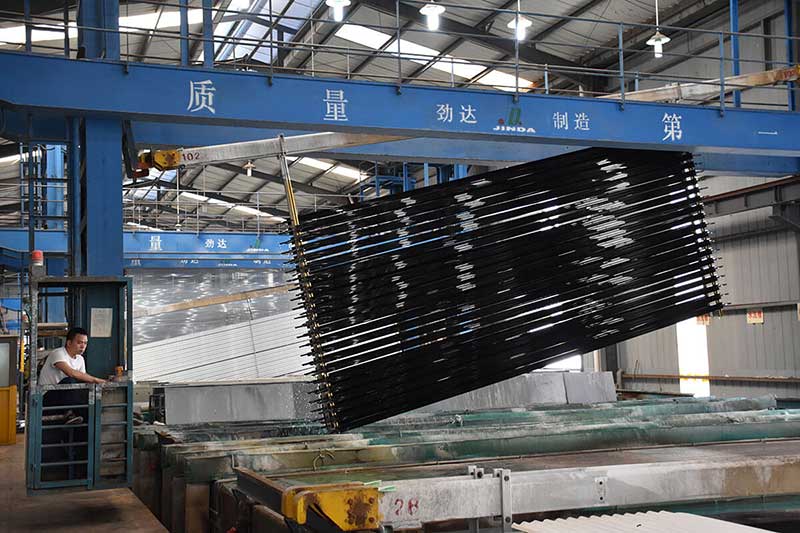

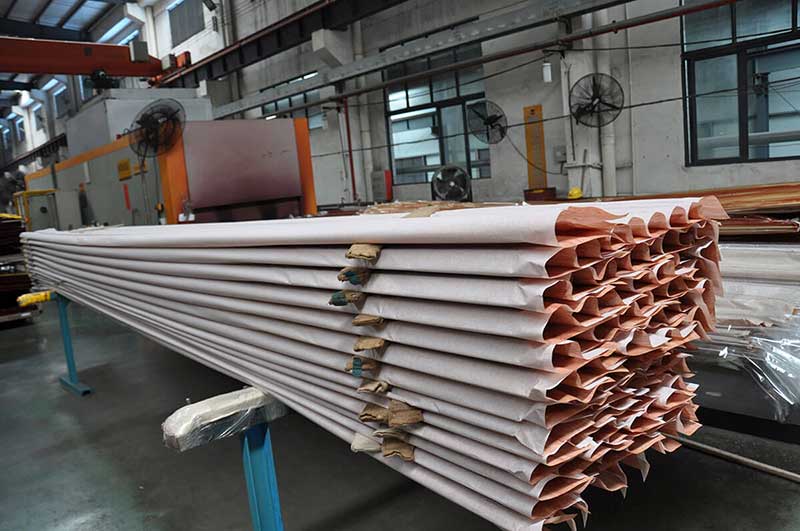

Our factory is located in Nanhai District Foshan City, which is one of the most professional gathering places for aluminum profiles in China. You can find many factories of aluminum profiles in Nanhai, but our factory is highly competitive in aluminum profiles in this industry. We have complete advanced production lines as below: 12 extrusion lines, 2 powder coating lines, 2 anodizing line, 2 transfer wood grain line, 1 mechanical polishing production line, 3 sandblasting production lines. We are a large-scale manufacturer of aluminum profiles for windows and doors and aluminum industrial profiles, covering 80,000 square meters, with annual output up to 38,000 tons.