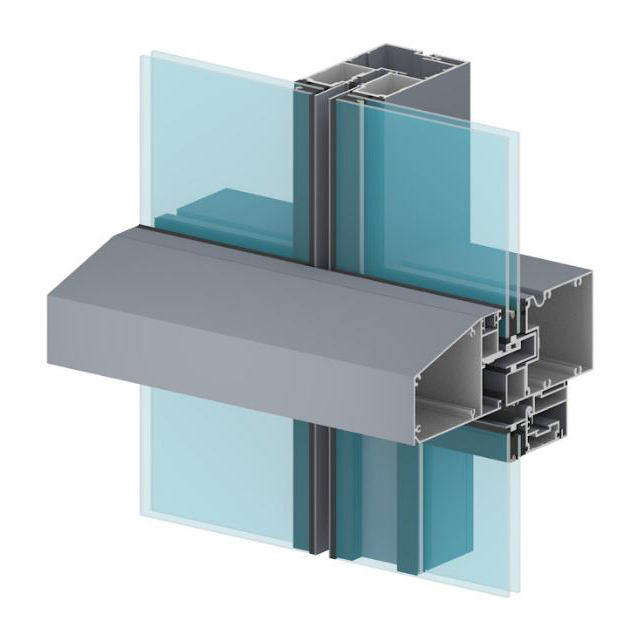

Production Process of Curtain Wall Aluminum Profiles

The production process of curtain wall aluminum profiles involves several stages, each with its own set of procedures and quality control measures. Here is a detailed overview of the entire process:

The Evolution of Curtain Wall Aluminum Profiles

Curtain wall systems have become a staple in modern architectural design, offering not only aesthetic appeal but also practical benefits such as energy efficiency and durability. At the heart of these systems lies the use of aluminum profiles, which have revolutionized the way buildings are clad and protected from the elements.

Aluminum profiles help lightweight rail transit development

In the first decade of the 21st century, rail transit in China and even the world has ushered in rapid development. However, this is also accompanied by problems such as energy consumption and environmental pollution. From the perspective of sustainable development, we should strive to reduce the weight of the vehicle itself when developing new rail vehicles to achieve the goal of reducing energy consumption.

The Prospects of Future Development of Aluminum Profile Manufacturing Industry

Aluminum profiles are a lightweight, corrosion-resistant and easy-to-process material that is widely used in construction, transportation, electronics and other fields. With the acceleration of global industrialization and the improvement of environmental awareness, the aluminum profile manufacturing industry is facing new development opportunities and challenges.

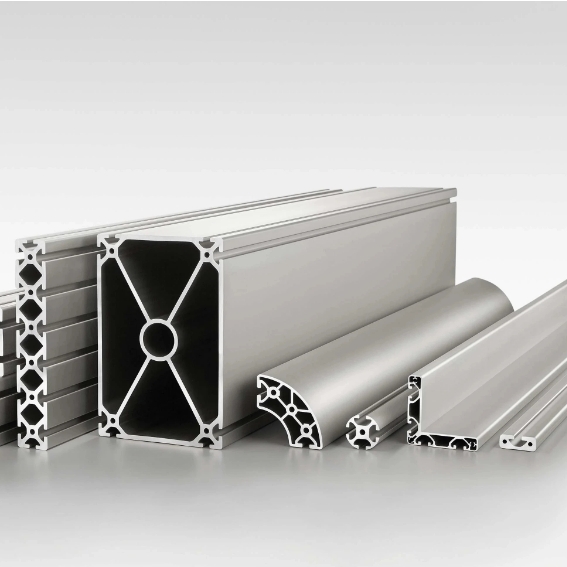

The Versatile Applications of Industrial Aluminum Profiles

Aluminum profiles have become an indispensable part of modern industry due to their unique properties and versatile applications. With the advancement of technology, the demand for aluminum profiles has increased significantly, making them a key material in various industries.

The Quality, Performance and Sustainability of Aluminum Profiles Reflect the Power of Industry

Aluminum profiles, like the exquisite tapestry of modern industry, skillfully weave together the solidity of quality, the excellence of performance and the sustainability, painted a brilliant picture of harmonious coexistence of technology and environmental protection. They are the crystallization of strength and beauty. Each aluminum profile carries the careful carving of craftsmen and the deep empowerment of technology. In terms of quality, they are as tenacious as steel, but show the elegant transcendence of weight with a lighter posture, as if they are the embodiment of the wind in nature, both powerful and agile.

The Marvelous World of Aluminum Alloys

Introduction:

Aluminum alloys have become an integral part of our daily lives, from the cans that hold our beverages to the aircraft that transport us across continents. These versatile materials offer a unique combination of properties that make them ideal for a wide range of applications. In this article, we will delve into the world of aluminum alloys, exploring their composition, properties, and the various industries that rely on them.

Industrial Aluminum Profiles Market 2024: New Trends and Driving Force

With the rapid development of global industry, the market demand for aluminum profiles, as a lightweight and high-strength industrial material, is ushering in a new round of growth. In 2024, the industrial aluminum profile market will show impressive new trends and driving force.

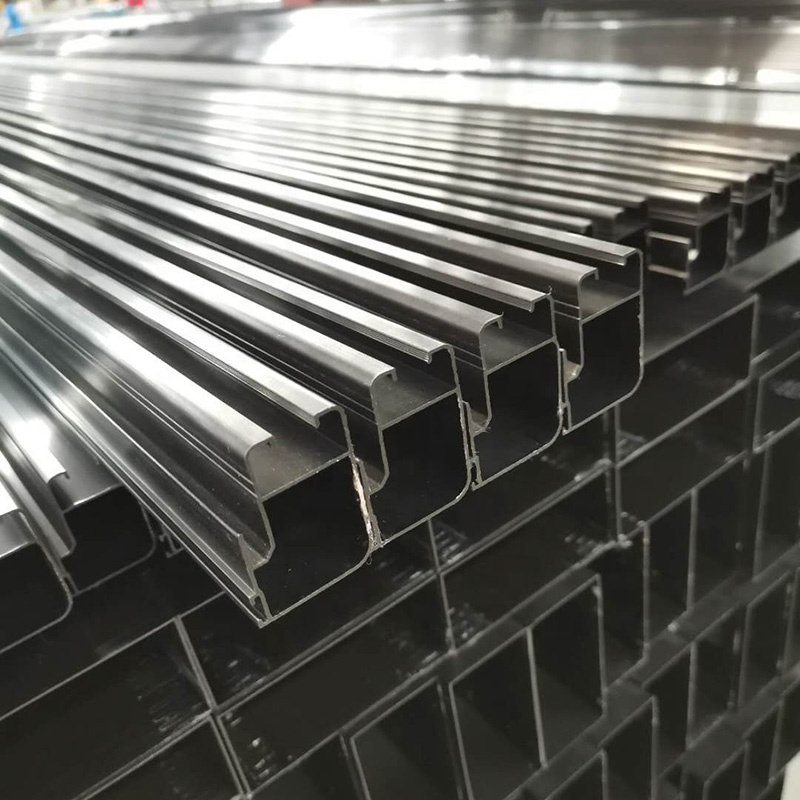

Aluminum Alloy Profiles

An aluminum profile factory is a facility where aluminum extrusions are produced. These factories are typically large-scale operations that involve several stages for production, from melting aluminum ingots to extruding the profiles and finishing them with various surface treatments.

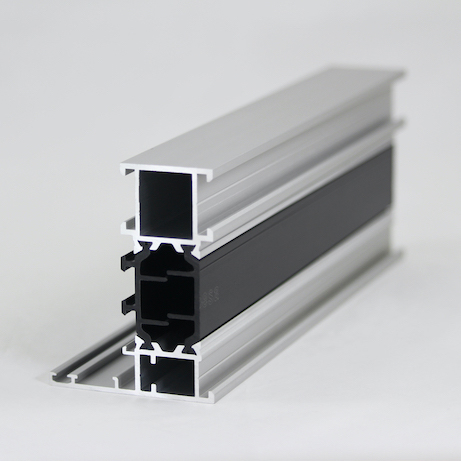

Thermal break aluminum profiles for doors and windows protect you from wind and rain, and loyally protect your home safety

An aluminum profile factory is a facility where aluminum extrusions are produced. These factories are typically large-scale operations that involve several stages for production, from melting aluminum ingots to extruding the profiles and finishing them with various surface treatments.