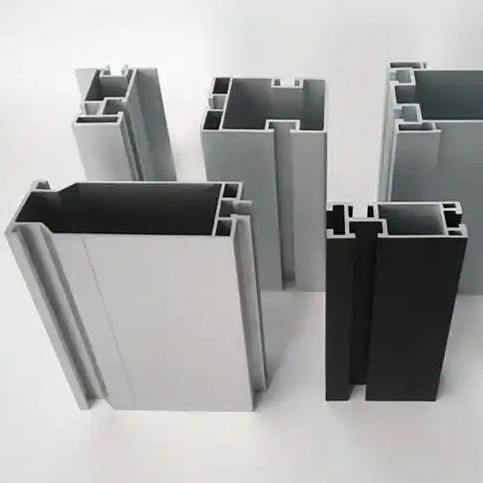

Production process and principle of aluminum alloy profile extrusion die

Aluminum alloy profile extrusion die is an important tool commonly used in industrial production. It extrude aluminum alloy materials into profiles of various cross-sectional shapes through specific processes and procedures. It is widely used in construction, transportation, electronics and other fields. Next, Intop Metal will introduce the production process and principle of aluminum alloy profile extrusion die.

How many thicknesses are there for thermal insulation aluminum profiles?

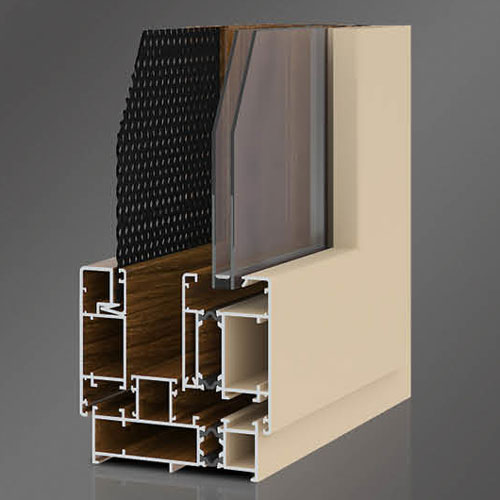

Thermally-broken aluminum profiles have been widely used in modern buildings, especially in the manufacture of doors and windows, due to their excellent heat insulation, sound insulation and thermal insulation properties. Regarding the thickness of thermally-broken aluminum profiles, it is not a single fixed value, but varies according to different design requirements, uses and national standards.

How to deal with paint corrosion on powder coated aluminum profiles?

Our company uses the best spray powder, and the material selection is strictly controlled. Generally, corrosion and paint peeling rarely occur. So, how to deal with corrosion and paint peeling of sprayed aluminum?

What is the standard for heavy duty sliding door aluminum profiles?

What are the standards for heavy-duty sliding door aluminum profiles? As an indispensable part of modern architecture, the standards of heavy-duty sliding door aluminum profiles directly determine the performance, safety and service life of the door. When purchasing heavy-duty sliding doors, it is crucial to understand and follow the relevant standards of aluminum profiles.

Metal Material Comparison: Steel and Aluminum

Metal is one of the most important industrial raw materials in the world, and steel and aluminum, as representatives of metal materials, have always been one of the most important materials in industry. There are obvious differences between the two in terms of properties and uses. This article will explore the comparison between steel and aluminum in depth.

Why choose aluminum alloy profiles instead of pure aluminum profiles?

The density of pure aluminum ingots is small, about 1/3 of that of iron, and the melting point is low. Aluminum is a face-centered cubic structure, so it has high plasticity. Aluminum alloy profiles are easy to process and can be made into various profiles and plates. It has good corrosion resistance, but the strength of pure aluminum is very low, so it is not suitable for structural materials.

Exploring the Advanced Applications of Aluminum Extrusion Deep Processing

Introduction:

Aluminum extrusion deep processing, also known as aluminum extrusion secondary processing, refers to the process of further refining and enhancing the properties and functionality of aluminum extrusions through various techniques. This article delves into the intricacies of aluminum extrusion deep processing, highlighting its benefits, processes, and applications in various industries.

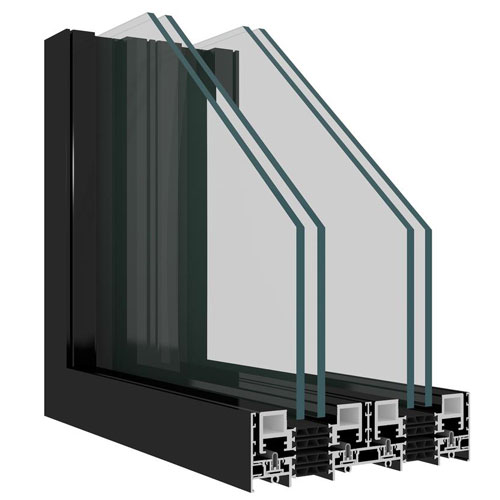

Advantages of Broken Bridge Aluminum Doors and Windows

1. Good sound insulation performance: Broken bridge aluminum doors and windows rely on the perfect combination of double-layer hollow glass and broken bridge structure to effectively block the spread of sound;

Solar Aluminum Profile

1. Introduction

Solar aluminum alloy profile is a material widely used in the field of solar photovoltaic. It has the advantages of light weight, high strength, corrosion resistance, good thermal conductivity, etc., and is widely used in the bracket system and component frame of solar photovoltaic power stations. This article will introduce solar aluminum alloy profiles in detail from multiple aspects such as material properties, production process application fields, etc.

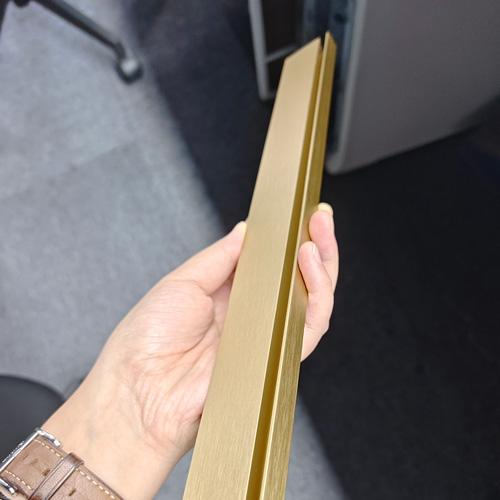

Exploring the Fascinating World of Aluminum Extrusion and Brass Drawing

Introduction:

The realm of aluminum extrusion and brass drawing is a fascinating one, filled with endless possibilities and applications. In this article, we will delve into the details of these processes, exploring their properties, advantages, and the various applications they serve in various industries.