How to repair the deformed aluminum alloy window frame?

The deformation of aluminum alloy window frame can be repaired by the following methods:

Initial repair: Use plastic hammer, wooden hammer, aluminum hammer or flat hammer to make initial repairs to the bent area. If this there is difficulties to do so, just heat the area and hammer it again. When repairing the corners, the aluminum alloy plate should be knocked from the back to avoid scratches and knocks on the panel.

Innovation in sandblasting treatment for aluminum products: a new way to improve surface texture

In the processing and treatment of aluminum products, surface treatment plays a vital role. As industrial design becomes increasingly sophisticated and consumers have higher requirements for product quality, the surface texture of aluminum products has become one of the important factors in evaluating their quality. Sandblasting, as an important surface treatment, has been revolutionized and applied in the aluminum products industry in recent years, bringing a more unique and advanced surface texture to aluminum products and opening up a new path to improve product quality.

Future Development Prospects of Aluminum Profile Manufacturing Industry

1. Background introduction

Aluminum profiles are a lightweight, corrosion-resistant and easy-to-process material with wide applications in construction, transportation, electronics and other fields. With the acceleration of global industrialization and the improvement of environmental awareness, the aluminum profile manufacturing industry is facing new development opportunities and challenges.

Performance comparison before and after aluminum surface treatment

Aluminum, as a lightweight, corrosion-resistant metal material, plays a pivotal role in modern industry. However, the original aluminum surface often lacks sufficient protection and is easily corroded and damaged by environmental factors, thus affecting its performance and lifespan. Therefore, surface treatment of aluminum materials has become a necessary technical means, which can not only improve the aesthetics of aluminum materials, but also significantly enhance its performance.

The Maintenance of Aluminum Alloy Doors and Windows

1. Push and pull lightly

When using aluminum alloy doors and windows, move gently and push and pull lightly. If you find any difficulties, do not push or pull it rudely, but you should eliminate the fault first.

2. Remove dust accumulation

Dust accumulation and deformation are the main reasons why aluminum alloy doors and windows are difficult to replace. Keep the door frame clean, especially the sliding groove. Use a vacuum cleaner to remove dust in the groove and door seal strips. When cleaning aluminum alloy doors and windows, do not step on the aluminum frame or hold the frame for support.

Eco-sustainability and Customization of Aluminum Window and Door

In the 21st century, it is normal and legitimate for people to care about environmental and sustainability issues. Among the advantages of aluminium is this: Aluminium is a completely environmentally friendly material because it is not harmful to the environment and does not release any toxic substances. Aluminium can therefore be considered a true green material, even when energy costs and production procedures are considered.

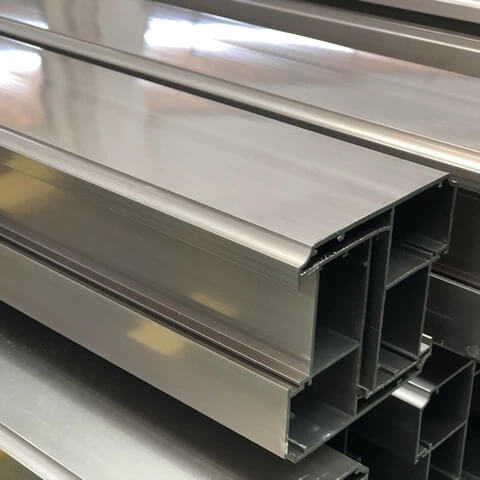

Characteristics of industrial aluminum profile frames made of aluminum profiles

Industrial aluminum profile frame is also a relatively common product of industrial profiles. It can be used to make various equipment brackets, load-bearing frames, etc. So what are the characteristics of industrial aluminum profile frames made of profiles? Let’s find out together:

The difference between thermal insulation aluminum alloy and Broken bridge aluminum alloy?

What is the difference between thermal insulation aluminum alloy and thermal break aluminum alloy? How to distinguish them? In the field of construction, there are two types of thermal insulation aluminum alloy and thermal break aluminum alloy. The two look very similar, but in fact there are many differences. The following will introduce the difference between the two.

Advantages of electrophoretic coating of aluminum profiles

Easy to realize automated production. Since the electrophoretic coating of aluminum profiles is carried out in a water-based electrophoretic tank, it is similar to anodizing and electrolytic coloring processes, with a short processing time, and it is easy to realize the assembly line operation of the entire process.

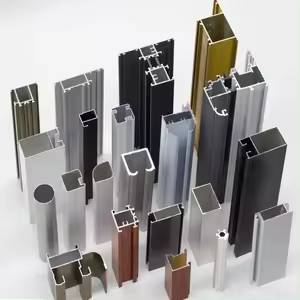

Identification method of aluminum alloy building profiles

Aluminum alloy building profiles are a kind of aluminum alloy hot extrusion profiles used for processing aluminum alloy doors, windows, glass curtain walls and for decoration. They are light, beautiful and durable, and are widely used in various types of construction and decoration industries.